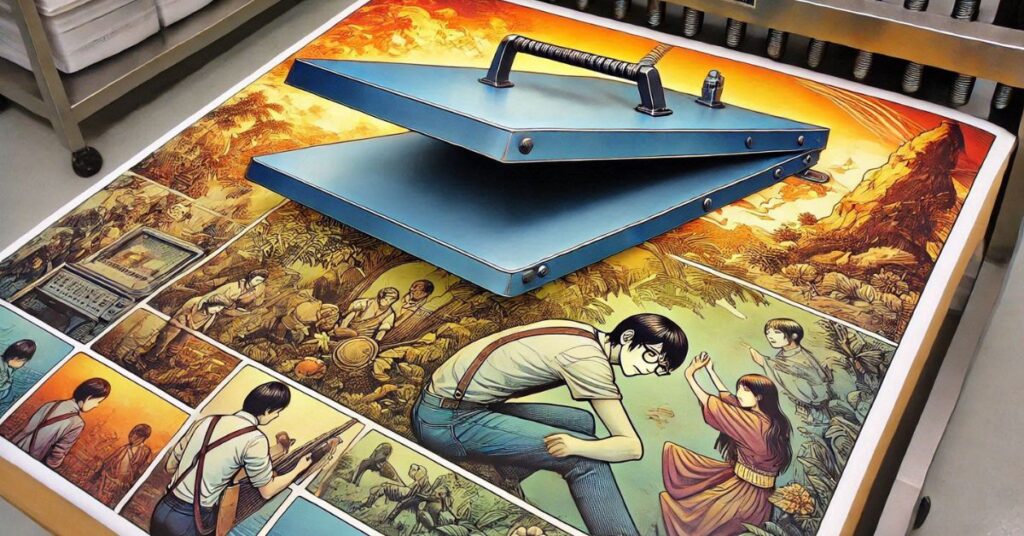

Minor Flaw on Upper Heat Press Platen both printing industry pros and enthusiasts, a heat press is an essential instrument. For transferring patterns onto materials like metal, ceramics, and textiles, it guarantees uniform pressure and heat distribution. A minor imperfection or roughness on the upper platen, however, may interfere with its operation and lower the calibre of your work. This post offers a thorough examination of the reasons, consequences, and workable fixes for this kind of problem, guaranteeing that your heat press continues to operate effectively and generate results of the highest caliber.

Also Read: https://everscroll.org/zilvinas-gudeliunas-and-kai-newton/

Understanding the Upper Heat Press Platen

In order to activate adhesives and inks during the transfer process, pressure is applied and heat is transferred to the heated upper platen of a heat press. The platen needs to be completely smooth, level, and heated uniformly for best results. Any flaws, even a minor bump, might have a detrimental impact on the transfer process, therefore it’s critical to spot and fix them right away.

Common Causes of Flaws or Bumps on the Upper Platen

Manufacturing Defects

During production, inconsistencies in materials or coatings may lead to small imperfections in the platen’s surface.

- Air bubbles, uneven finishes, or faulty calibration can create bumps.

Wear and Tear

- Over time, regular use of the heat press can lead to dents, scratches, or distortions.

- Heavy use without proper maintenance accelerates the development of imperfections.

Improper Storage and Handling

- Storing the heat press in environments with high humidity, excessive heat, or physical impact can deform the platen.

- Placing heavy or sharp objects on the platen may also cause dents or bumps.

Residual Debris or Build-Up

- Adhesives, inks, lint, or debris from previous transfers can harden on the platen, creating uneven spots.

- Neglecting regular cleaning exacerbates this issue.

Effects of a Bump on Heat Press Performance

Uneven Pressure Distribution

- The presence of a bump creates an uneven surface, causing inconsistent pressure during the transfer process.

- This inconsistency may lead to incomplete transfers, especially on larger designs.

Transfer Imperfections

- A bump can leave visible marks or indentations on the material, compromising the final product’s appearance.

- The flaw might also distort the design, making it look unprofessional.

Reduced Durability

- Uneven pressure affects the adhesion of transfer materials, leading to reduced durability and peeling of the design over time.

Increased Material Waste

- Imperfect transfers often result in wasted materials and time, reducing overall efficiency and profitability.

Steps to Identify a Bump on the Upper Platen

Visual Inspection

- Examine the surface of the platen under good lighting to spot visible flaws, bumps, or dents.

Tactile Check

- Run your hand over the platen’s surface to feel for irregularities.

Test Press

- Use a sheet of thin, heat-sensitive paper or fabric to perform a test press. Uneven pressure will reveal itself through inconsistent heat marks or transfer quality.

Solutions for a Small Flaw or Bump on the Upper Platen

1. Clean the Platen

- Use a soft cloth and a heat press cleaner to remove any adhesive, lint, or residue.

- Avoid abrasive cleaners or tools that could worsen the flaw.

2. Sanding Minor Bumps

- For minor imperfections, gently sand the area using fine-grit sandpaper.

- Smooth the surface carefully to avoid damaging the platen further.

3. Use a Heat Press Pad

Put a cushion of foam or silicone between the material and the platen. By distributing pressure uniformly, these pads help make up for little imperfections.

4. Replace the Platen

Replace the platen if the bump is too big or cannot be repaired. Numerous vendors provide machine-compatible replacement components.

5. Seek Professional Repair

Speak with a qualified technician or the heat press’s maker if there are any serious flaws. Defects in manufacture may be covered by warranty or repair services.

Preventative Measures

Regular Maintenance

- Clean the platen after every use to prevent residue build-up.

- Use heat press covers to protect the surface from adhesives and inks.

Proper Storage

- Store the heat press in a clean, dry environment away from extreme temperatures and humidity.

- Avoid placing heavy or sharp objects on the platen.

Routine Inspections

- Periodically inspect the platen for any signs of wear, dents, or bumps. Early detection allows for timely fixes.

Use Protective Sheets

- Use Teflon or parchment paper during transfers to prevent debris from sticking to the platen.

When to Replace the Upper Platen

While minor flaws can often be repaired, there are cases where replacing the platen is the best option. Consider a replacement if:

- The bump or flaw significantly affects transfer quality.

- The platen’s surface is worn out or uneven.

- Repairs are no longer effective or feasible.

Conclusion(Minor Flaw on Upper Heat Press Platen)

Although a minor imperfection or bump on the upper heat press platen may not seem like much, it can significantly affect the efficiency, longevity, and quality of the transfer. Consistent, expert outcomes are guaranteed when the reasons are recognised and the problem is resolved quickly. Your heat press’s lifespan may be increased and future flaws can be less likely with routine maintenance, cautious handling, and preventative actions. To ensure optimal performance in cases of severe problems, expert help or platen replacement may be required.

FAQs

1. Can I still use a heat press with a bump on the upper platen?

Yes, but using a heat press pad or silicone sheet can help minimize the impact of the flaw on your transfers.

2. How do I know if the bump is affecting my transfers?

Uneven pressure or visible imperfections in your transfers are clear indicators that the bump is causing problems.

3. Is replacing the platen expensive?

Replacement costs vary by brand and model. Check with the manufacturer for specific pricing and compatibility.

4. What’s the best way to clean the upper platen?

Use a soft cloth and a heat press-specific cleaner to remove debris without damaging the surface.

5. Can preventative measures completely avoid bumps?

While proper care and maintenance significantly reduce the risk, regular inspections are essential to address early signs of wear or damage.